| Roodhart 811 ANSI Process Pumps | |||

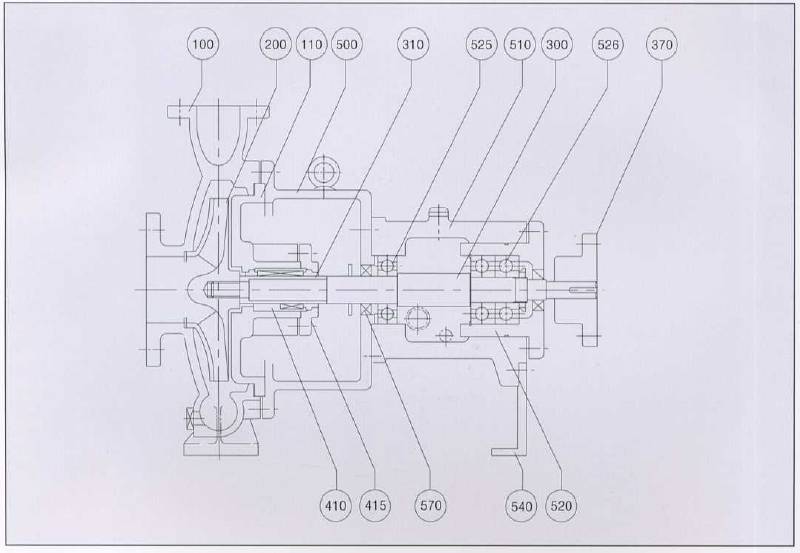

| The fully open impeller, centerline discharge, and other unique design features allow the 811 to continue operating long after other ANSI pumps wear out or break down. A choice of extra-heavy-duty, stocked, Ductile Iron, Stainless Steel, Alloy 20 and CD4M pump materials coupled with multiple seal design options allows you to tailor the 811 to virtually any process flow application. The fully-open impeller design features large wear areas and back pump-out vanes, making the 811 far superior in handling corrosive and erosive fluids. Open impellers balance hydraulic axial thrust loads, lengthen bearing life, and reduce stuffing box pressure too. And best of all, the Model 811 is available in a wide range of sizes and capacities to fit virtually any process fluid application. The Roodhart 811 ANSI pump can make your life simpler by replacing a warehouse full of pumps, including Goulds 3196, Peerless 8196, Durco Mark II / III, Ingersoll Rand HOC and other ANSI pumps available on the market. Please contact us for more information about pricing and interchangeability, engineerded solutions and complete pump packages. | ||||

| ||||

| Roodhart 811 ANSI Process Pumps – Design Features | ||||

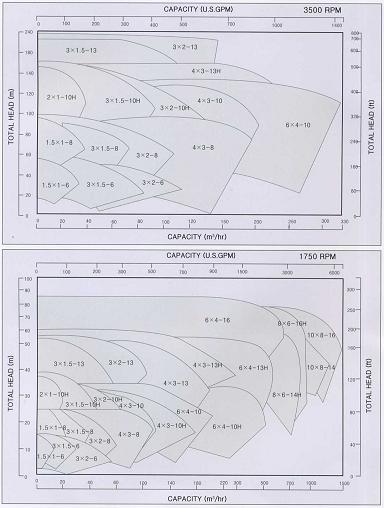

| Maximum Capacity | Up to 1400 M³ | |||

| Maximum Head | Up to 130 m. | |||

| Power Supply | 3 phase 50 / 60 Hz. | |||

| Material Design | All Ductile Iron | All Monel | ||

| All Stainless 316 | All Hastelloy | |||

| All Alloy 20 | Titanium Grades ( on request available ) | |||

| All CD4M | ||||

| Pump Sizes | Discharge sizes from 1″ up to 8″ | |||

| Applications | Petrochemical | Pulp & Paper | ||

| Oil & Gas | Chemical | |||

| Water treatment | Food Processing | |||

| Power Generation | ||||

| Downloads in | No information available yet. | |||

| More Information | e-mail:buypump@hanmail.net | |||

Roodhart 811